Ever wonder why there are so many distinct colors available for fiber optic cables? The selection is not random! From the outer jacket to the connection tip, every color on a fiber optic cable represents a specific signal path. To ensure they always use the correct product for the customer, professionals utilize an industry-standardized “color code” system to readily identify the type of fiber they are working with. The Telecommunications Industry Association (TIA), which created the crucial TIA-598 standard for color-coding and other essential standards for fiber identification, oversees this universal language.

Let’s explore this simple yet universal language of color and see how it helps to connect our digital world.

The fundamental elements of the cable are quickly and visually listed by color. A technician can quickly determine the rated throughput capacity and the types of equipment it is compatible with by examining the jacket or connector. Because intermixed fiber types can result in a degradation of performance or even damage to sensitive network equipment, proper color-coding of networking components helps to ensure end-to-end link integrity.

In the fiber industry, using standardized colors has several useful benefits:

Quick Identification: Technicians can avoid wasting time examining small, sometimes faded printed lettering on the cable jacket during installation or troubleshooting; the type of fiber core can usually be quickly determined by its outer jacket color.

Reduced Errors: Color coding enables efficient performance verification during the installation process and reduces troubleshooting time if something were to go awry.

Simple Organization: The inner color codes make it easier for personnel to properly sort, label, and manage each fiber strand in big network deployments where hundreds of signals may pass through a single conduit.

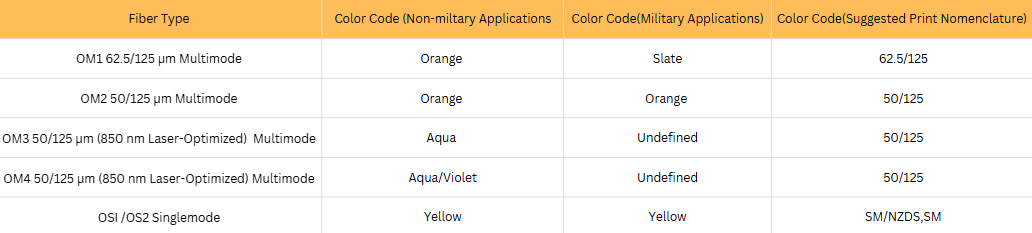

Your first hint is the primary color of the jacket. It classifies the fiber according to its transmission capacity (commonly referred to as Singlemode for long distances, and Multimode for small distances, such as inside a building).

Here’s a quick summary of some of the more popular jacket colors in the industry:

Fiber Type |

Common Jacket Color |

What it means |

|

OM1 & OM2 Multimode |

Orange |

This is standard fiber, often used for slower, older networks. |

|

OM3 Multimode |

Aqua |

This is a high-speed fiber, optimized for fast connections like 10 Gigabit speeds and higher. |

|

OM4 Multimode |

Aqua/Violet |

An even faster version of OM3, built for extended reach in data centers. |

|

OM5 Multimode |

Lime Green |

Designed for short wavelength division multiplex applications. It’s great for 100+Gb transmission. |

| OS1 & OS2 Singlemode | Yellow |

This is the fiber used for the longest distances, such as connecting different cities or large campuses. |

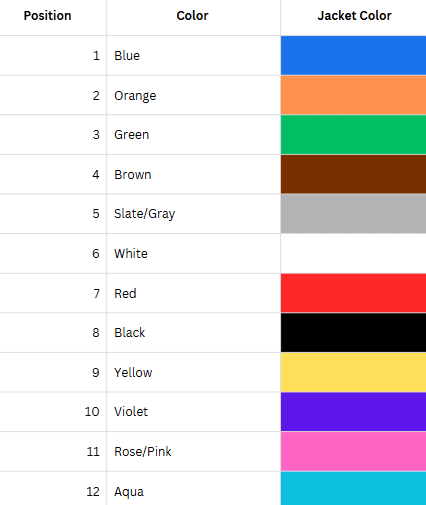

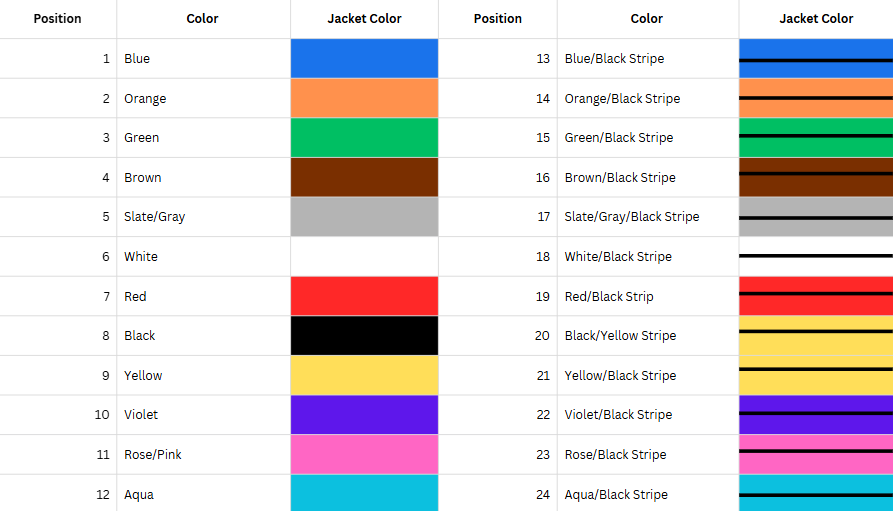

Many individual hair-thin glass strands are found inside a fiber optic trunk cable. Each fiber is given a color according to its location within the TIA-598 standard. Twelve colors are used in a repeating sequence:

The Twelve-Color Standard Sequence:

The colors of the first 12 strands are solid and follow this easy pattern:

The process is repeated if there are 24 strands in the cable. Each fiber from Position 13 to Position 24 has a unique Black Stripe painted on it to indicate that it is a member of the second group, even though they all use the same 12 colors.

Acronym |

Stands For |

Polish Type |

Description |

|

PC |

Physical Contact | Standard |

The fiber end-face is polished slightly spherical (rounded) to ensure the fiber cores meet directly. |

|

UPC |

Ultra Physical Contact | Improved PC |

A higher quality, more refined version of PC polish, resulting in a flatter end-face and lower back-reflection (better performance). |

|

APC |

Angled Physical Contact | Angled | The end-face is polished at an angle to prevent light reflected off the connection from traveling back down the fiber (best performance/lowest back-reflection). |

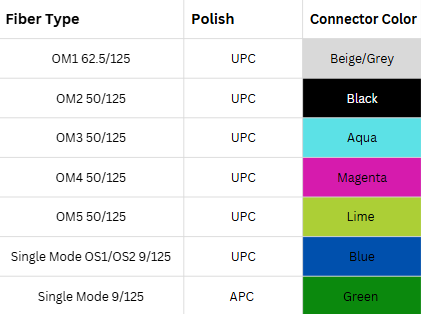

The color of the connector boot or housing is one of the most important color codes to know. It tells you both the fiber type and the specific polish on the end of the glass strand.

Blue and green connector colors are the two most crucial for single-mode cables, because they typically indicate a difference in the physical connection.

Blue Connectors (UPC): The end-face polish of these is slightly convex. They are the norm for most single-mode networks.

Applications:

Green connectors (APC): The connector end-face is polished at an 8° angle; in high-performance, extremely sensitive applications (such as long-distance video or high-power laser communications), this angle is employed because it keeps reflected light from interfering with the transmission signal.

Applications:

The fiber optic color coding system, which is regulated by standards such as the TIA-598, is a simple but effective tool that gives complex, fast networks the required efficiency and order. These colors are the unconscious guides that help technicians construct and maintain the dependable, high-speed infrastructure that we all rely on, whether you’re tracking the blue/black stripe strand inside a trunk, identifying an OM5 connecting cable on the data center floor, or ensuring a proper APC mated connection where you need it.

When you’re looking for the absolute best in fiber connectivity, you need a partner whose expertise is forged in decades of history and high-precision manufacturing. The best connectivity solutions aren’t just off-the-shelf; they come from a legacy of over 35 years of experience, dedicated to creating the highest-quality, most precise solutions available. This kind of deep knowledge ensures your cables meet the rigorous demands of every sector, from general industry to military applications. Choosing a manufacturer with this kind of commitment and history means choosing reliability and peak performance.

For your cable assembly needs, with a focus on high precision, deep industry experience, and creating the best possible product, reach out to Gruber Communication Products at 800.658.5883 or 602.863.2655 or email support@gruber.com.

For many years, coaxial wire has been one of the most reliable

Learn More →Fiber Optic Connector Fiber optic technology continues to evolve as organizations demand

Learn More →