Gruber Communications Ladder Rack

Efficient cable management is essential in today’s data centers, telecom rooms, and

Learn More →

The custom cable assembly industry is experiencing rapid growth due to the increasing demand for high-speed data transmission, customized solutions, and enhanced durability. Custom cable assemblies are essential for businesses in the telecommunications, healthcare, data center, and industrial automation sectors to ensure continuous operation. Manufacturers are coming up with new ideas to satisfy customer demand for tailor-made, high-speed cabling solutions that offer reliability, efficiency, and flexibility.

A custom cable assembly is a specific group of conductors that are bundled together, terminated with a particular connector, and quality control tested to meet customer-specific requirements—rather than a generic, cookie-cutter, off-the-shelf design.

Unlike COTS (commercial off-the-shelf), custom cable products are typically tailored to:

Length & Size: cut and arranged to fit exact applications

Connector: chosen or designed to match the equipment and environment.

Material & Shielding: selected for durability, EMI/RFI protection, or resistance to heat, chemicals, moisture, or vibration.

Performance needs: designed for required data rates, power capacity, or signal integrity.

Custom cabling solutions are primarily utilized in telecommunication, medical, aerospace, military, and entertainment industries, where reliability, space constraints, and environmental conditions demand specialized solutions.

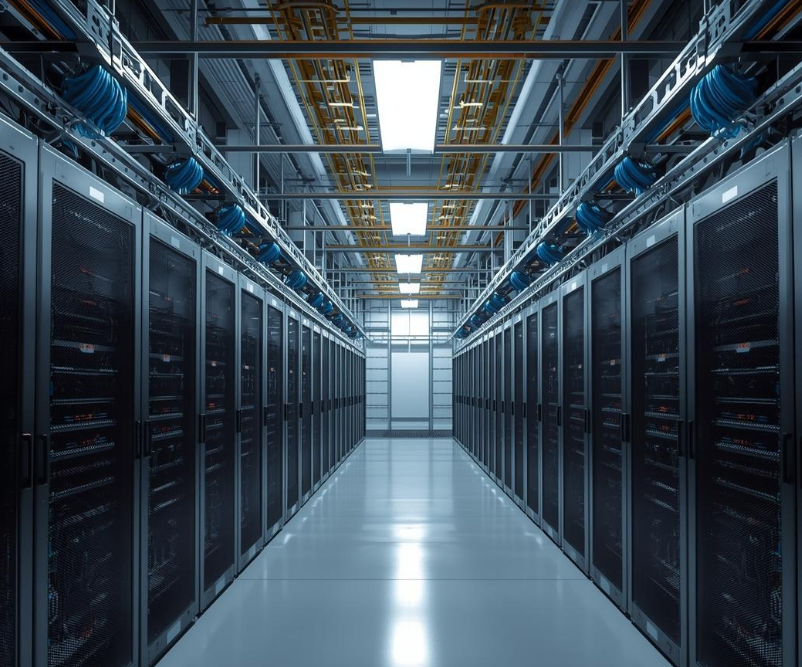

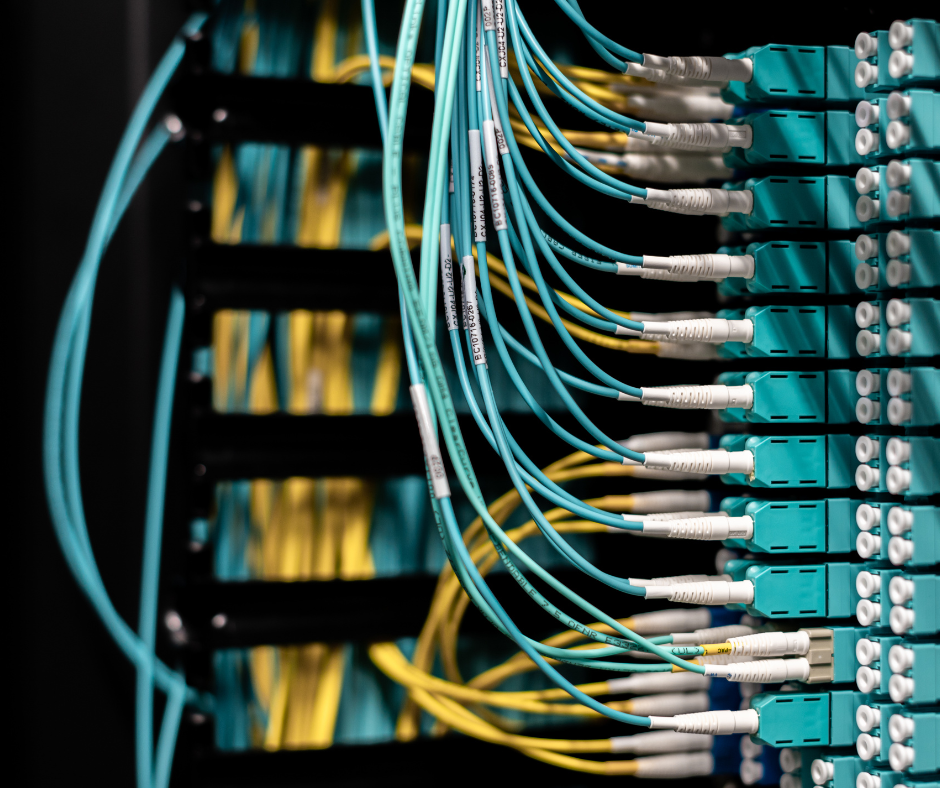

Modern technology is getting more compact and integrated. To match these devices, the cable connected to them also needs to be miniaturized and custom-made to ensure system functionality without any signal degradation. For example, medical imaging equipment relies on slim, shielded cables to transmit a massive amount of data in real-time without interference. In data centers, miniaturized assemblies provide a higher bandwidth while improving the air flow and overall efficiency of the system. These precision-engineered solutions ensure reliable connectivity in even more demanding applications.

One of the easiest ways to reduce environmental impact is by using custom cables that are high quality, last longer, and require less replacement. Additionally, the use of sustainable materials that are biodegradable plastics and the adoption of energy-efficient manufacturing techniques are necessary to reduce the environmental footprint of cables.

The process of collecting data at the exact moment it is generated is called real-time monitoring. This data is then analyzed to help industries make informed, data-driven decisions that improve operational efficiency. Real-time monitoring provides accurate insights, enhances process control, and often reduces costs. Custom Ethernet cable assemblies play a key role in enabling this by ensuring reliable, high-speed data transmission. When selecting the right cable, factors such as transmission rate, distance, and environmental conditions must be considered. Additionally, compatibility between cables and connected systems is crucial for achieving optimal performance.

For military and industrial applications where reliability in extreme conditions is critical, custom cable assemblies are indispensable. These cables are engineered with reinforced shielding, ruggedized jackets, and specialized connectors to withstand exposure to heat, vibration, moisture, dust, and harsh chemicals, ensuring uninterrupted performance. By contrast, ruggedized cables with IP68-rated connectors provide durable, weather-resistant connections ideally suited for demanding live events such as concerts and stage productions.

The global custom cable assembly market is closely aligned with the broader cable assembly industry, which was valued at USD 178.90 billion in 2024 and is projected to reach USD 253.81 billion by 2030, growing at a CAGR of 6.05% from 2025 to 2030 (Grand View Research, Cable Assembly Market Report,2025SEP23). Within this landscape, the custom assembly segment already accounts for a larger share than pre-assembled or off-the-shelf cables, and demand for tailored, high-performance solutions is expected to accelerate steadily through 2030.

Gruber Communication Products is the leading custom cable assembly manufacturer in Phoenix, Arizona, with over 40 years of experience serving all industries and major tech firms nationwide. Our expertise goes beyond simple manufacturing; we are a full-service custom solution provider, offering:

Our commitment to quality is underscored by our unprecedented lifetime warranty on all manufactured products, a testament to our confidence in the durability and dependability of our solutions. Choosing Gruber Communication Products means you are partnering with a company dedicated to excellence, ensuring your critical infrastructure is protected and optimized for peak performance.

The custom cable assembly market is driven by trends like miniaturization, smart manufacturing, and the need for real-time data in critical applications. As industries demand specialized, high-performance solutions that withstand extreme conditions, companies must innovate. With over 40 years of experience, Gruber Communication Products is a leader in this field, providing custom-engineered, high-quality assemblies backed by an unprecedented lifetime warranty, ensuring reliability and performance for the future. Contact Gruber Communication Products for more information: 800.658.5883 or 602.863.2655 or email support@gruber.com.

Efficient cable management is essential in today’s data centers, telecom rooms, and

Learn More →For many years, coaxial wire has been one of the most reliable

Learn More →