Gruber Communications Ladder Rack

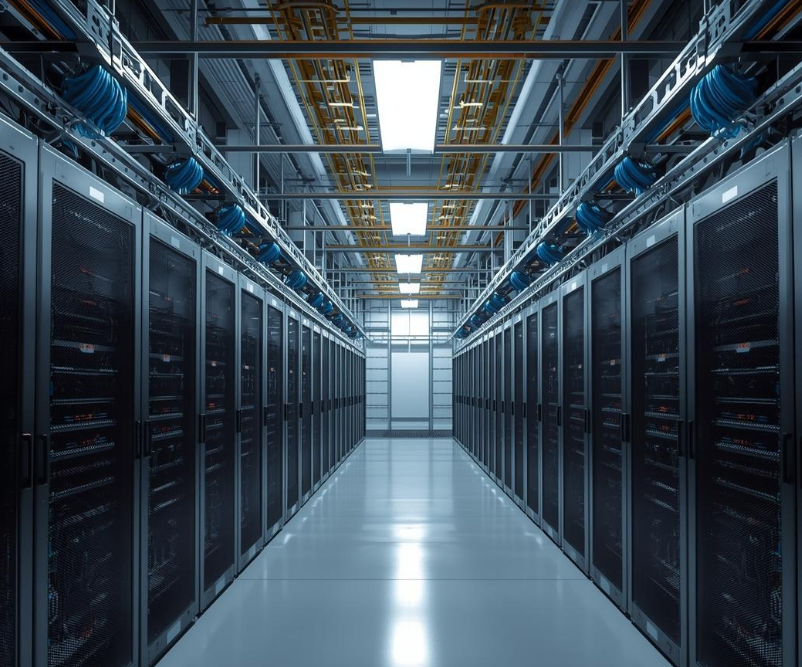

Efficient cable management is essential in today’s data centers, telecom rooms, and

Learn More →

Bootless Vs Boot Cables: By Gruber Communication Products

When setting up a network, whether a large data center or a small office, every detail matters, including the smallest detail on the connectors. While some 8p8c RJ45 connectors offer similar connectivity regardless of the Ethernet cable selected, the variation in finished good assembly with boots or without boots can greatly affect the durability, usability, and how network patch assemblies can be organized.

Among IT professionals and enthusiasts, the debate over which style reigns supreme continues. Ultimately, the decision depends on your application and environment. To help you select the best networking choice, let’s clarify what a boot is, its various varieties, and its benefits and drawbacks.

The rubber sleeve or the molded plastic that encases the point where the cable jacket meets the RJ45 connector is called a boot. The core function of the boot is to relieve strain and prevent damage or loosening of the cables from the connector when the cables are pulled, bent, or handled.

Boots also serve a vital role in protecting the locking clip on RJ45 connectors. This tiny locking clip is essential to keep the cable securely in place. If it breaks, the cable will be useless, as the connection will be prone to slipping out with the smallest pull.

Snagless Boots: They are also known as the bubble/snag-proof boots; these are an essential element for the IT world. Snagless boots are little protective covers over the locking clip that prevent the cables from snagging on other equipment, cables, or wires. This protection is invaluable when you’re pulling multiple cables through crowded conduits or wire management systems, preventing the clip from snapping off. These types of boots are superior for applications where regular patching/repatching is the norm.

Narrow boot: These are mostly called slim/low-profile boots, which refer to the small plastic or rubber protective sleeves found at the end of an Ethernet patch cable, where the cable meets the RJ45 connector.

Working with cables might be drastically changed by the variations in boot design. For instance, some snagless boots (often called “bubble” boots) can make it difficult to press the locking clip in a densely packed panel, leading to the development of more streamlined designs like the “Slimline” boot, which offers connector snag protection but with easier clip access.

|

Feature |

Snagless/Bubble Boots |

Low Profile / Narrow Boots |

|

Primary Goal |

Helps protect the modular connector locking clip from breaking | Minimize the cable exit profile for higher-density use |

|

Clip Protection |

Excellent, durable |

Premium, aesthetic |

|

Connector size |

Legacy size has the most color and sizing options for bulky cable usage |

Compact and slim, designed for higher port densities |

|

Ease of connecting and disconnecting |

It can be slightly harder to press the clip due to the protective flap, depending on the design |

Generally, it is easier to manipulate in tight spaces due to its minimal size |

| Best Use | Low-density environment, pulling cables through conduits or cable bundles where snagging is a concern; high-traffic areas. |

High-density data centers, patch panels, server racks, or anywhere space is extremely limited. |

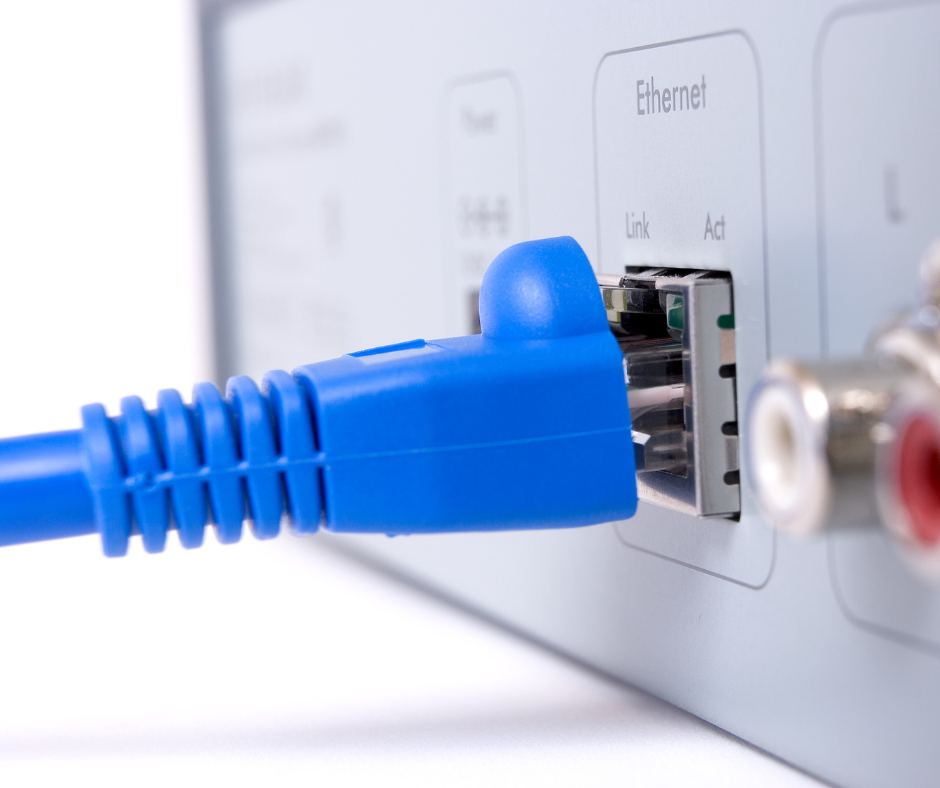

An Ethernet cable that lacks the covering on the connector is referred to as a bootless Ethernet cable. This means that the cable jacket ends right at the back of 8p8c (RJ45) plug, leaving the lockup clip open and exposed.

High Density: Bootless assemblies have minimal profiles, and they are a good choice for high-gang-stacked patching environments; they fit neatly side-by-side in high-port-density network switches and patch panels.

Easy access to lock clip: The exposed locking clip is easy to press and release, allowing for a faster and effortless connection and disconnection, which is essential for maintenance and troubleshooting.

Aesthetics: Some network engineers forgo boots simply to meet customer expectations.

|

Feature |

Booted Ethernet Cable (Snagless) |

Bootless Ethernet Cable |

|

Primary Benefit |

Connector Protection & Durability |

Space Efficiency & Ease of Use |

|

Clip Protection |

Excellent (Snagless) / Good (Molded) |

None (Highly Prone to Breakage) |

|

Strain Relief |

Excellent (Protects the Termination) |

None (Prone to Internal Damage) |

|

Ideal Environment |

Desks, Laptops, Conduits, Temporary Installs, Industrial Settings |

High-Density Patch Panels, Network Switches, Data Center Racks |

|

Ease of Connecting/Disconnecting |

It can be difficult in tight spaces |

Very easy, even in tight spaces |

|

Cable Management |

Can add bulk to large bundles |

Slim, easy to route, and saves space |

|

Durability |

High | Low (Easily damaged if not handled with care) |

Selecting between booted and bootless Ethernet cables is not a choice of one being fundamentally “better” than the other to matching a product to a solution.

Choose Booted Cables: When you have cables that are frequently moved, handled, or run through conduits. This includes connections to end-user devices like laptops, desktop PCs, and cable road kits. The snagless boot is a nominal investment that offers a longer cable life and prevents unintended disconnection frustration.

Choosing Bootless Cables: These cables will be installed in a high-density, permanent environment like a tightly packed server rack, network switch, or patch panel, where space is at an absolute premium and the cable will rarely, if ever, be unplugged. The slimmer profile is worth the trade-off in durability in these fixed, high-volume scenarios.

Sometimes, an off-the-shelf solution just won’t cut it. For complex wiring harnesses, unique connector configurations, or specialized wiring harness assemblies, you want a technology partner who will listen to your needs to manufacture a solution.

For any custom cable assembly, wiring harness manufacturing, and communication circuit manufacturing needs right here in Phoenix, Arizona, you should try

Gruber Communication Products, the trusted experts for custom connectivity solutions. Contact: 800.658.5883 or 602.863.2655 or email: support@gruber.com

Efficient cable management is essential in today’s data centers, telecom rooms, and

Learn More →For many years, coaxial wire has been one of the most reliable

Learn More →