Gruber Communications Ladder Rack

Efficient cable management is essential in today’s data centers, telecom rooms, and

Learn More →

In today’s digital world, downtime is more than just an inconvenience; it’s a serious threat to productivity, revenue, and customer trust. Whether it’s a data center, hospital, or manufacturing plant, every second of downtime can be extremely costly.

Most companies focus heavily on their servers, software, or power systems to ensure uptime. However, one critical component that’s mostly overlooked is cable assemblies, which play a vital role in both network performance and power reliability.

While standard off-the-shelf cables may be sufficient for basic applications, businesses operating in critical mission environments often need more. Custom cable assemblies provide seamless operations, reduce downtime, and help to prevent costly downtime.

In this blog, we’ll explore why custom cable assemblies are the best choice for critical networks and how they’re becoming essential for businesses looking to future-proof their infrastructure.

The cost of downtime extends far beyond lost productivity minutes; it can cripple an organization’s operations, financing, and/or reputation. On average, downtime in a data center with a 70% outage can range anywhere from $100,000 – 1 million per hour. Even for small or mid-sized companies, a single outage can be devastating, leading to several issues like loss of sales, missed deadlines, interrupted production, and long-term reputational damage.

Data Center: Downtime can trigger massive financial, operational, and reputational damage.

Manufacturing operations: A single hour of downtime can cost between $50,000-$150,000, depending on the scale of the facility and products. Beyond financial loss, it can disrupt the supply chain, cause equipment stress and damage, employee idle time, quality control, and safety issues.

Hospitals: In the healthcare industry, downtime isn’t just about money; it’s about lives, which means a small downtime or disrupted connectivity can lead to medical errors, delayed treatment, compliance violations, and severe reputational damage.

Custom cable assemblies are specifically engineered to meet unique operational requirements. Unlike standard off-the-shelf cables, these assemblies are designed with the exact length, shielding, termination, and connector needed to seamlessly fit required specifications.

Tailored, Application-Specific Design: Built to exact specification, including length, gauge, shielding, and connector type, by eliminating unnecessary bulk and ensuring seamless integration.

High-quality Material: Options include halogen-free, flame-retardant, shielded/unshielded, and medical-grade performance, with jacket materials selected to suit the operating environment.

Pre-Terminated and Tested: These custom cables are factory terminated with professional–grade connectors. Finished goods also undergo rigorous testing for continuity, signal integrity, and stress testing before deployment.

Faster Deployment and Maintenance: Simplifies setup, troubleshooting, and replacement, minimizing downtime and overall maintenance time.

Durability and Protection: Ruggedized designs are available for harsh environments with shielding to protect signal integrity.

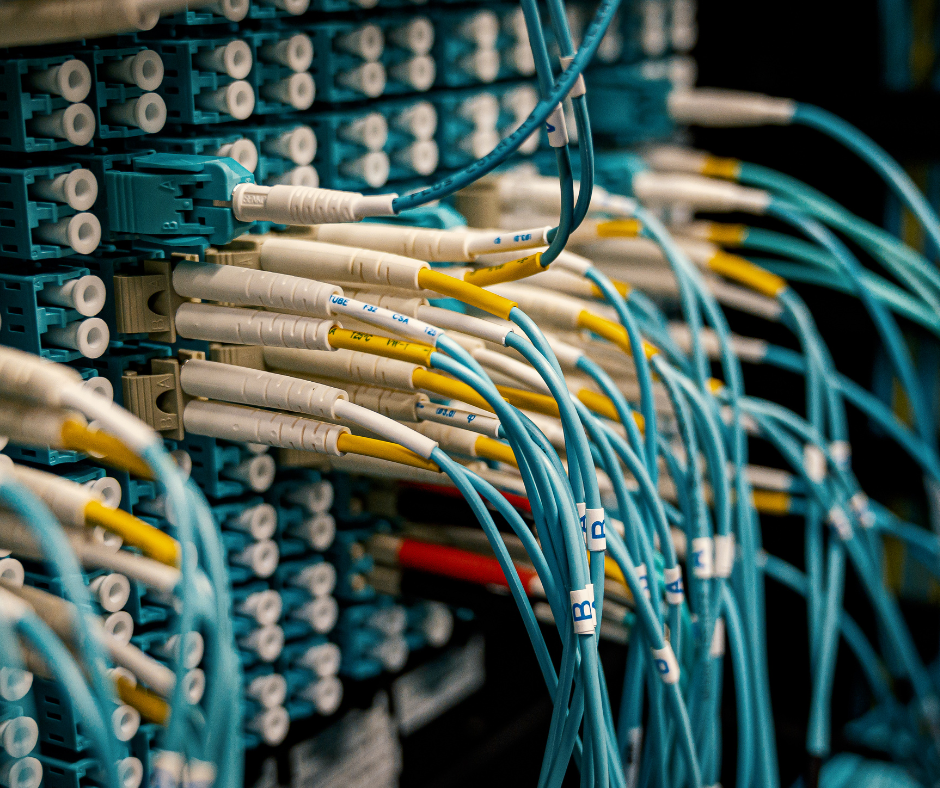

Improved Cable Management: Custom-length cables prevent unnecessary bulk, improve airflow, and make maintenance easier. Assemblies can be labeled, bundled, and color-coded as required.

Industry Compliance: Manufactured in accordance with industry standards and industry-specific certifications ensures long-term reliability and product safety.

Standard off-the-shelf cables are designed for general use, which often leads to overextension, bending, or even a connector mismatch. These physical stresses can cause premature wear and failure. Custom cable assemblies, on the other hand, are cut short into exact lengths with the right connector, reducing strain and extending cable life.

Custom cable assemblies are pre-engineered and clearly labeled, making installation faster, easier, cleaner, and error–free by eliminating common human mistakes.

When standard cables are exposed to outdoor or extreme conditions, they quickly degrade under stress. Custom cable assemblies are built with rugged jackets, shielding, and waterproof ratings (IP65, IP66, IP67) to ensure reliable performance even in the harshest environments.

In data-heavy environments, signal integrity is everything. Poorly shielded or mismatched cables can cause issues like interference, outages, and packet loss. Custom assemblies are specifically engineered with the right shielding and bandwidth support, delivering stable, interference-free performance that minimizes downtime.

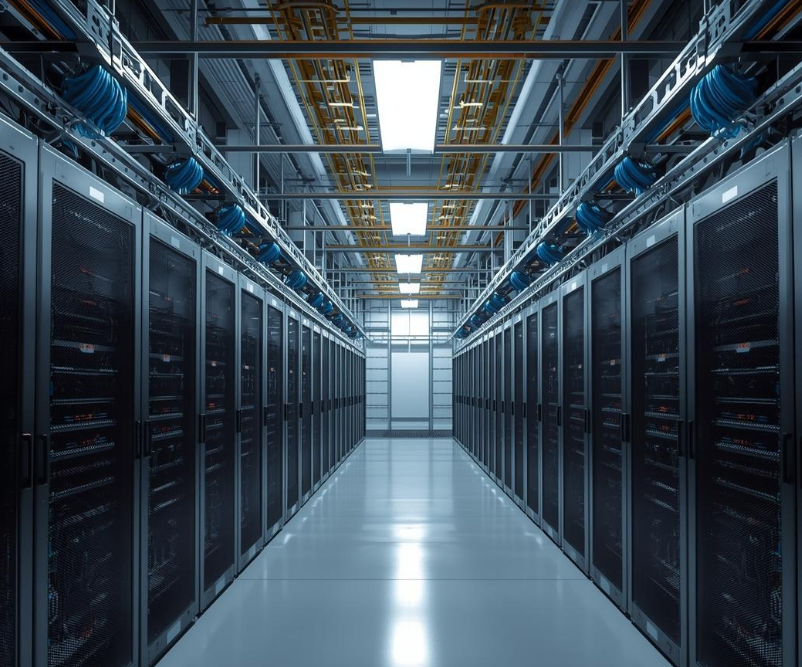

Data Center: Thousands of cables run across racks to servers, and poor cable management can lead to overheating, crosstalk, and hard-to-trace connectivity failures. Custom cable assemblies reduce cable clusters, improve airflow, and enable optimized routing for better overall performance.

Manufacturing and Industrial Automation: In a manufacturing plant, machines such as robots, conveyors, and sensors must work seamlessly together. Custom cable assemblies maintain a reliable connection, even in tough conditions, resisting electrical interference, bending, movements, heat, dust, oil, and chemicals. This ensures smooth 24×7 operation with minimal disruption.

Healthcare Facilities: In healthcare, every second counts. Patient monitors, imaging equipment, infusion pumps, the hospital communication network; all these systems must stay online to ensure patient safety. Custom medical-grade cable assemblies are designed to provide reliable, uninterrupted operation in this challenging environment.

Event and Entertainment Industry: Live concerts, festivals, broadcasts, and stage production all depend on flawless audio, video, and lighting connections. Professionals rely on rugged custom cables, including etherCON® assemblies, that withstand constant plugging, foot traffic, rain, and rough handling.

Military and Defense Sector: For defense and military applications, downtime isn’t just costly; it is mission critical. Communication systems, radar, UAVs, navigation — every system relies on rugged and secure connections to perform under extreme conditions. Custom cable assemblies in this sector meet MIL–SPEC requirements to ensure reliability and durability for Armed Forces.

Founded in 1984 and based in Phoenix, Arizona, Gruber Communications offers over 40 continuous years of expertise in designing, manufacturing, and supplying top-rated cabling solutions according to your needs. We are proud to be recognized as one of the leading custom cable assembly manufacturers in Phoenix and nationwide, delivering solutions that businesses can rely on.

What do we offer:

Whether you need a single prototype or high-volume production, Gruber Communications is your trusted partner for custom cable assemblies built to last.

In today’s world, where downtime can be extremely costly and businesses rely heavily on reliable power and connectivity, custom cables are not optional but essential. Investing in custom cable assemblies today means you are investing in your future. Whether you are running a data center, factory, or hospital, the right cable solution is the strongest defense against costly interruption. Contact Gruber Communications today for your custom cable assembly solution: Home – Gruber Communications

Call: 800.658.5883 or 602.863.2655 or email support@gruber.com

etherCON® is a registered trademark of Neutrik AG. All rights reserved.

Efficient cable management is essential in today’s data centers, telecom rooms, and

Learn More →For many years, coaxial wire has been one of the most reliable

Learn More →